Understanding Chamfering Machines: An Essential Tool for Precision Manufacturing

Summary:

Chamfering machines are integral tools in the manufacturing and processing industries, particularly in scenarios requiring precision finishing and edge preparation. These machines are designed to bevel the edges of metal, plastic, and other materials, creating a smooth transition between surfaces. By effectively removing sharp edges, chamfering machines not only enhance the aesthetic appeal of com

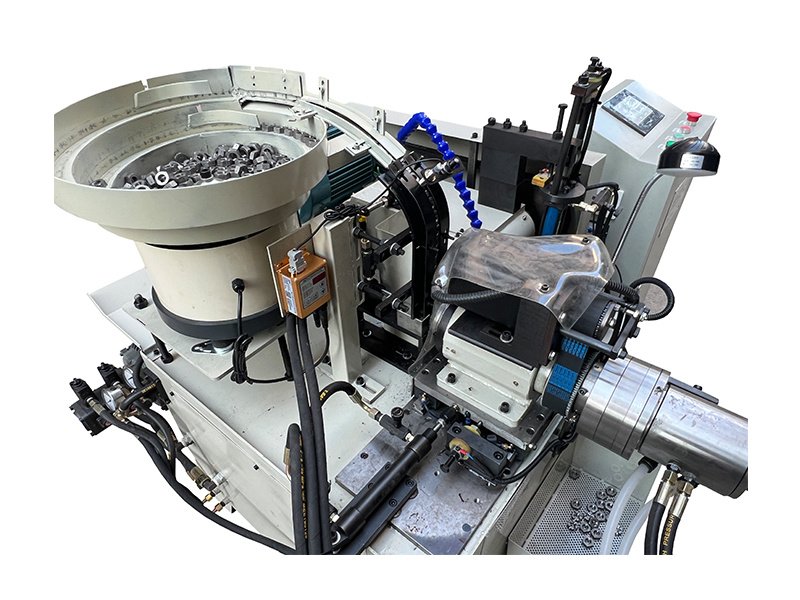

Chamfering machines are integral tools in the manufacturing and processing industries, particularly in scenarios requiring precision finishing and edge preparation. These machines are designed to bevel the edges of metal, plastic, and other materials, creating a smooth transition between surfaces. By effectively removing sharp edges, chamfering machines not only enhance the aesthetic appeal of components but also improve safety and functionality in assembly operations.

The primary function of a chamfering machine is to create a beveled edge at a specified angle, typically between 15 to 45 degrees. This process is essential for numerous applications, including preparing parts for welding, ensuring proper fitment in assemblies, and facilitating easier handling during post-manufacturing processes. The reduction of sharp edges through chamfering minimizes the risk of injury during handling and installation, which is a crucial consideration in workplace safety.

One of the significant advantages of using a chamfering machine is the efficiency it brings to metalworking operations. Modern electric chamfering machines are designed for quick and effective processing, allowing operators to achieve consistent results with minimal effort. These machines often feature adjustable settings, enabling users to customize the beveling angle and depth according to specific requirements. This adaptability makes them suitable for various materials, including steel, aluminum, and plastics, accommodating a wide range of projects.

Moreover, chamfering machines contribute to improved production quality. By ensuring that edges are uniformly beveled, they help in reducing the risk of defects during subsequent manufacturing steps, such as welding or assembly. This consistency is vital for large-scale production runs where precision can significantly impact overall performance and product reliability.

In addition to their core functionalities, chamfering machines often come equipped with advanced features such as dust extraction systems and adjustable speed controls. These enhancements not only optimize tool performance but also promote a cleaner working environment, reducing airborne particles that can compromise air quality and operator health.

The versatility of chamfering machines extends beyond traditional manufacturing settings. They are also widely used in crafts, repairs, and custom fabrication, making them a valuable addition to any toolkit. With the increasing focus on quality and safety in manufacturing, the role of chamfering machines has become more prominent, establishing them as essential assets in various industries.

In summary, understanding the role of chamfering machines is crucial for professionals involved in manufacturing and processing. These machines offer numerous benefits, enhancing efficiency, safety, and production quality. By investing in advanced chamfering technology, businesses can improve their operations and meet the demanding standards of today’s manufacturing landscape.

The primary function of a chamfering machine is to create a beveled edge at a specified angle, typically between 15 to 45 degrees. This process is essential for numerous applications, including preparing parts for welding, ensuring proper fitment in assemblies, and facilitating easier handling during post-manufacturing processes. The reduction of sharp edges through chamfering minimizes the risk of injury during handling and installation, which is a crucial consideration in workplace safety.

One of the significant advantages of using a chamfering machine is the efficiency it brings to metalworking operations. Modern electric chamfering machines are designed for quick and effective processing, allowing operators to achieve consistent results with minimal effort. These machines often feature adjustable settings, enabling users to customize the beveling angle and depth according to specific requirements. This adaptability makes them suitable for various materials, including steel, aluminum, and plastics, accommodating a wide range of projects.

Moreover, chamfering machines contribute to improved production quality. By ensuring that edges are uniformly beveled, they help in reducing the risk of defects during subsequent manufacturing steps, such as welding or assembly. This consistency is vital for large-scale production runs where precision can significantly impact overall performance and product reliability.

In addition to their core functionalities, chamfering machines often come equipped with advanced features such as dust extraction systems and adjustable speed controls. These enhancements not only optimize tool performance but also promote a cleaner working environment, reducing airborne particles that can compromise air quality and operator health.

The versatility of chamfering machines extends beyond traditional manufacturing settings. They are also widely used in crafts, repairs, and custom fabrication, making them a valuable addition to any toolkit. With the increasing focus on quality and safety in manufacturing, the role of chamfering machines has become more prominent, establishing them as essential assets in various industries.

In summary, understanding the role of chamfering machines is crucial for professionals involved in manufacturing and processing. These machines offer numerous benefits, enhancing efficiency, safety, and production quality. By investing in advanced chamfering technology, businesses can improve their operations and meet the demanding standards of today’s manufacturing landscape.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us