Unlocking the Potential of CNC Thread Rolling Machines in Modern Manufacturing

Summary:

CNC Thread rolling machines are advanced manufacturing tools designed to create threads on cylindrical materials through a process known as thread rolling. Unlike traditional cutting methods, which carve away material to form threads, thread rolling uses mechanical pressure to shape the material, resulting in stronger and more precise threads. These machines are particularly valued in industries t

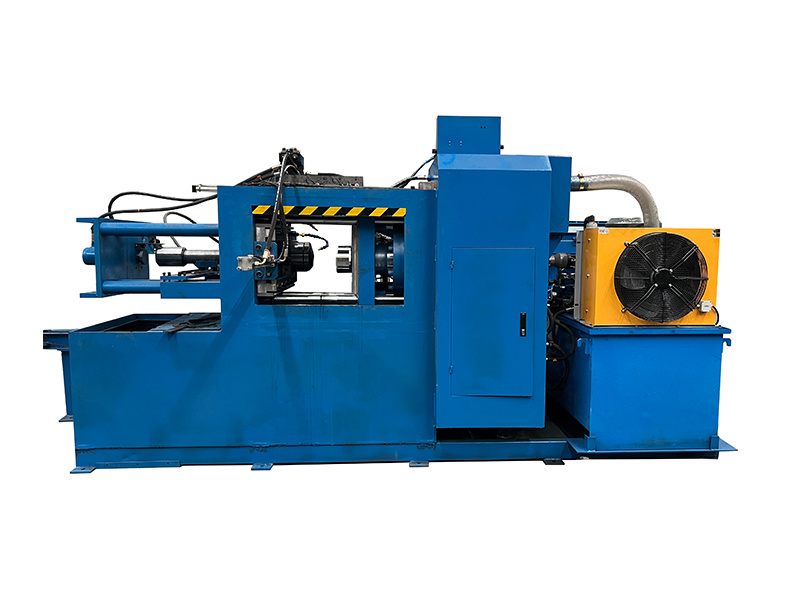

CNC Thread rolling machines are advanced manufacturing tools designed to create threads on cylindrical materials through a process known as thread rolling. Unlike traditional cutting methods, which carve away material to form threads, thread rolling uses mechanical pressure to shape the material, resulting in stronger and more precise threads. These machines are particularly valued in industries that require high-volume production and tight tolerances.

One of the primary advantages of CNC thread rolling machines is their ability to produce threads without removing material. This cold-forming process enhances the strength of the threads, as the fibers of the material remain continuous rather than being severed. This characteristic makes rolled threads more resistant to wear and fatigue, leading to increased durability of the final product. Additionally, because there is no chip formation, the process is cleaner and more environmentally friendly compared to traditional machining methods.

CNC (Computer Numerical Control) technology takes the capabilities of thread rolling machines to the next level by allowing for automated and highly precise operations. With CNC capabilities, manufacturers can program the machine to produce complex thread patterns and sizes with minimal human intervention. This not only speeds up production times but also significantly reduces the risk of human error, leading to consistent quality in the finished products.

The applications of CNC thread rolling machines are vast and varied. They are commonly used in the automotive, aerospace, and electronics industries, where precision and reliability are paramount. For example, manufacturers can produce bolts, screws, and fittings that require exact specifications to ensure safety and performance in critical applications. Furthermore, as industries increasingly shift towards automation and smart manufacturing, CNC thread rolling machines are becoming an integral part of modern production lines.

Another noteworthy feature of CNC thread rolling machines is their ability to efficiently handle a variety of materials, including steel, aluminum, and plastics. This versatility allows manufacturers to adapt to changing market demands and experiment with new materials without the need for extensive retooling. As a result, businesses can maintain flexibility in production while reducing costs associated with material waste and rework.

In conclusion, CNC thread rolling machines represent a significant advancement in manufacturing technology. Their ability to create strong, precise threads through a non-cutting process provides manufacturers with numerous advantages, including higher efficiency, superior product quality, and greater flexibility. As industries continue to embrace automation and strive for excellence in production, the role of CNC thread rolling machines will likely expand, making them indispensable tools in modern manufacturing environments.

One of the primary advantages of CNC thread rolling machines is their ability to produce threads without removing material. This cold-forming process enhances the strength of the threads, as the fibers of the material remain continuous rather than being severed. This characteristic makes rolled threads more resistant to wear and fatigue, leading to increased durability of the final product. Additionally, because there is no chip formation, the process is cleaner and more environmentally friendly compared to traditional machining methods.

CNC (Computer Numerical Control) technology takes the capabilities of thread rolling machines to the next level by allowing for automated and highly precise operations. With CNC capabilities, manufacturers can program the machine to produce complex thread patterns and sizes with minimal human intervention. This not only speeds up production times but also significantly reduces the risk of human error, leading to consistent quality in the finished products.

The applications of CNC thread rolling machines are vast and varied. They are commonly used in the automotive, aerospace, and electronics industries, where precision and reliability are paramount. For example, manufacturers can produce bolts, screws, and fittings that require exact specifications to ensure safety and performance in critical applications. Furthermore, as industries increasingly shift towards automation and smart manufacturing, CNC thread rolling machines are becoming an integral part of modern production lines.

Another noteworthy feature of CNC thread rolling machines is their ability to efficiently handle a variety of materials, including steel, aluminum, and plastics. This versatility allows manufacturers to adapt to changing market demands and experiment with new materials without the need for extensive retooling. As a result, businesses can maintain flexibility in production while reducing costs associated with material waste and rework.

In conclusion, CNC thread rolling machines represent a significant advancement in manufacturing technology. Their ability to create strong, precise threads through a non-cutting process provides manufacturers with numerous advantages, including higher efficiency, superior product quality, and greater flexibility. As industries continue to embrace automation and strive for excellence in production, the role of CNC thread rolling machines will likely expand, making them indispensable tools in modern manufacturing environments.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us