The Ultimate Guide to Double Head Chamfering Machines: Enhancing Efficiency in Manufacturing

Summary:

Double head chamfering machines are specialized tools essential for various manufacturing applications, particularly when a clean and precise edge is required. These machines feature two cutting heads that operate simultaneously, significantly increasing productivity by allowing for dual-sided chamfering in a single pass. This capability not only enhances efficiency but also ensures uniformity and

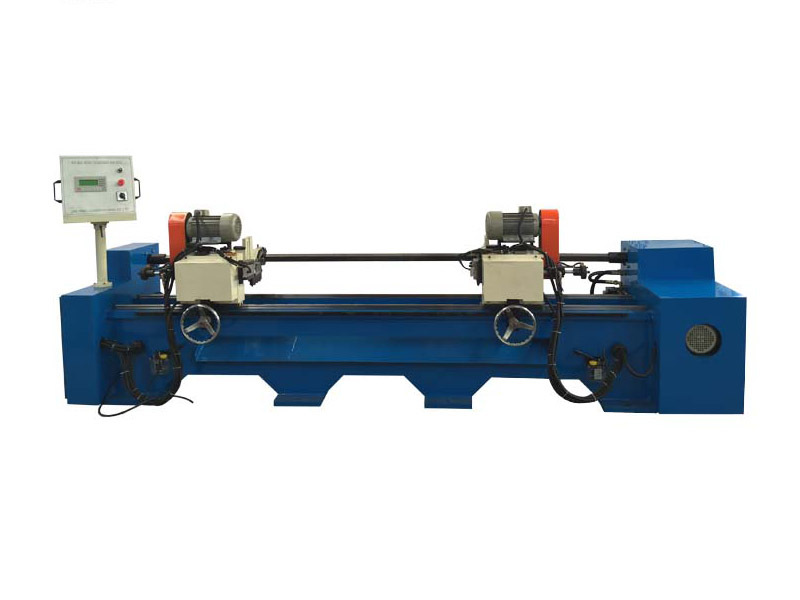

Double head chamfering machines are specialized tools essential for various manufacturing applications, particularly when a clean and precise edge is required. These machines feature two cutting heads that operate simultaneously, significantly increasing productivity by allowing for dual-sided chamfering in a single pass. This capability not only enhances efficiency but also ensures uniformity and accuracy, crucial for high-quality manufacturing standards.

One of the primary advantages of a double head chamfering machine is its ability to handle a variety of materials, including metals, plastics, and composites. This versatility makes it an invaluable asset in industries such as automotive, aerospace, and general engineering, where precision is paramount. The machine can perform different chamfer angles and depths, accommodating a wide range of specifications and customer requirements.

In addition to productivity gains, double head chamfering machines are designed to enhance operator safety and ease of use. Many models come equipped with advanced safety features, such as emergency stop buttons and protective enclosures, ensuring that operators can work without the constant worry of accidents. Moreover, user-friendly controls and automated settings simplify the setup process, allowing operators to achieve optimal results with minimal training.

When selecting a double head chamfering machine, it is essential to consider factors such as the machine’s cutting speed, feed rate, and compatibility with different tooling options. The right machine should align with your specific production needs and provide flexibility for future projects. Moreover, investing in a machine with robust construction and reliable components will minimize downtime and maintenance costs, ultimately contributing to a more profitable operation.

To maximize the performance of your double head chamfering machine, regular maintenance is crucial. This includes routine inspections, cleaning, and lubrication of moving parts. Additionally, operators should be trained to recognize signs of wear and tear, enabling them to address issues before they lead to significant downtime or repairs.

In conclusion, double head chamfering machines are a critical component of modern manufacturing, providing efficiency, precision, and versatility. By understanding their benefits and best practices, manufacturers can leverage these machines to achieve superior results while enhancing overall productivity. Whether you are considering a new purchase or looking to optimize your current setup, a double head chamfering machine can be a game-changer for your operations.

One of the primary advantages of a double head chamfering machine is its ability to handle a variety of materials, including metals, plastics, and composites. This versatility makes it an invaluable asset in industries such as automotive, aerospace, and general engineering, where precision is paramount. The machine can perform different chamfer angles and depths, accommodating a wide range of specifications and customer requirements.

In addition to productivity gains, double head chamfering machines are designed to enhance operator safety and ease of use. Many models come equipped with advanced safety features, such as emergency stop buttons and protective enclosures, ensuring that operators can work without the constant worry of accidents. Moreover, user-friendly controls and automated settings simplify the setup process, allowing operators to achieve optimal results with minimal training.

When selecting a double head chamfering machine, it is essential to consider factors such as the machine’s cutting speed, feed rate, and compatibility with different tooling options. The right machine should align with your specific production needs and provide flexibility for future projects. Moreover, investing in a machine with robust construction and reliable components will minimize downtime and maintenance costs, ultimately contributing to a more profitable operation.

To maximize the performance of your double head chamfering machine, regular maintenance is crucial. This includes routine inspections, cleaning, and lubrication of moving parts. Additionally, operators should be trained to recognize signs of wear and tear, enabling them to address issues before they lead to significant downtime or repairs.

In conclusion, double head chamfering machines are a critical component of modern manufacturing, providing efficiency, precision, and versatility. By understanding their benefits and best practices, manufacturers can leverage these machines to achieve superior results while enhancing overall productivity. Whether you are considering a new purchase or looking to optimize your current setup, a double head chamfering machine can be a game-changer for your operations.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us