Boosting Productivity with Automatic U Bolt Bending Machines: A Comprehensive Guide

Summary:

Boosting Productivity with Automatic U Bolt Bending Machines: A Comprehensive Guide

Table of Contents

1. Understanding U Bolt Bending Machines

2. Importance of Productivity in Manufacturing

3. How Automatic U Bolt Bending Machines Work

4. Benefits of Using Automatic U Bolt Bending Machines

5. Key Features to Consider When Selecting a Machine

6. Best Practices

Boosting Productivity with Automatic U Bolt Bending Machines: A Comprehensive Guide

Table of Contents

- 1. Understanding U Bolt Bending Machines

- 2. Importance of Productivity in Manufacturing

- 3. How Automatic U Bolt Bending Machines Work

- 4. Benefits of Using Automatic U Bolt Bending Machines

- 5. Key Features to Consider When Selecting a Machine

- 6. Best Practices for Optimizing Productivity

- 7. Common Challenges and Solutions

- 8. Future Trends in U Bolt Bending Technology

- 9. Frequently Asked Questions

- 10. Conclusion

1. Understanding U Bolt Bending Machines

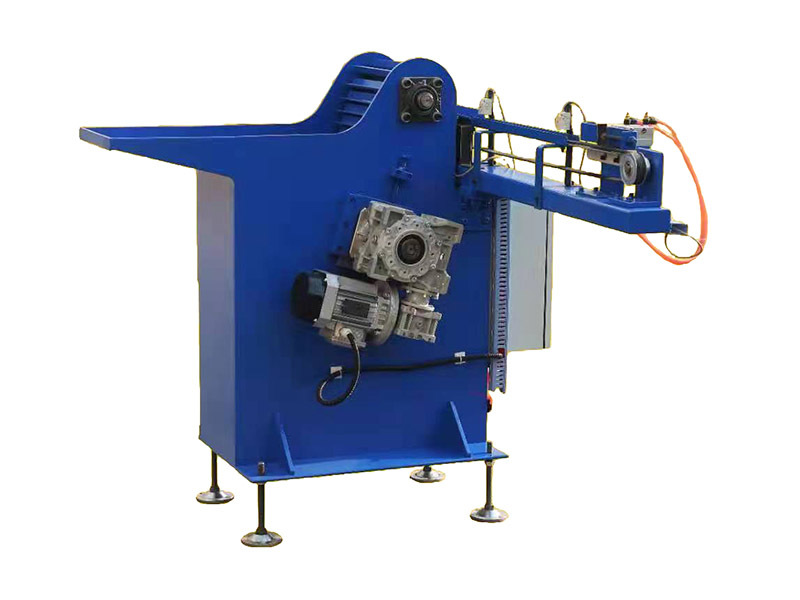

Automatic U bolt bending machines are specialized equipment designed to bend metal rods into the shape of U bolts, which are crucial components in various industries, including automotive, construction, and manufacturing. These machines automate the bending process, ensuring consistency, accuracy, and efficiency.

The Role of U Bolts in Manufacturing

U bolts serve as essential fasteners that hold components together securely. Their applications range from automotive suspensions to anchoring structures, making them indispensable in numerous manufacturing processes.

2. Importance of Productivity in Manufacturing

In today's competitive landscape, **manufacturing productivity** is a critical factor that determines the success of any operation. Higher productivity levels reduce costs, enable faster order fulfillment, and enhance customer satisfaction. Companies that invest in technologies like automatic U bolt bending machines position themselves for growth and market leadership.

Measuring Productivity

Productivity can be measured in various ways, including output per labor hour, machine efficiency, and production cycle times. Understanding these metrics allows manufacturers to identify areas of improvement and leverage advanced machinery for optimal performance.

3. How Automatic U Bolt Bending Machines Work

Automatic U bolt bending machines utilize advanced technology to automate the bending process. They typically feature programmable controls that allow operators to input specifications, such as the desired angle and length of the U bolt.

The Bending Process

The bending process begins with feeding a metal rod into the machine. The machine then uses hydraulic or mechanical force to bend the rod into the required shape. Advanced sensors ensure precise measurements, reducing the likelihood of errors.

Different Types of Bending Techniques

- **Hydraulic Bending**: Uses hydraulic power to achieve desired shapes, ideal for thicker materials.

- **Electric Bending**: Offers faster operation and is often more energy-efficient.

- **Mechanical Bending**: Utilizes mechanical levers for bending, suitable for lighter applications.

4. Benefits of Using Automatic U Bolt Bending Machines

Investing in automatic U bolt bending machines offers numerous advantages that can significantly boost productivity.

Increased Accuracy and Consistency

Automated machines minimize human errors, ensuring that every U bolt meets precise specifications. This consistency is crucial for maintaining product quality and reliability.

Enhanced Speed and Efficiency

Automatic machines can produce U bolts at a much faster rate compared to manual bending. This speed translates into shorter production cycles and the ability to meet higher demands without compromising quality.

Cost Savings

While the initial investment in an automatic U bolt bending machine may be significant, the long-term savings from reduced labor costs, minimized waste, and improved operational efficiency make it a worthwhile investment.

Improved Workplace Safety

Automation reduces the need for manual labor in hazardous tasks, enhancing safety for workers and minimizing the risk of workplace accidents.

5. Key Features to Consider When Selecting a Machine

When choosing an automatic U bolt bending machine, several features should be taken into account.

Programmable Controls

Machines equipped with user-friendly programmable controls allow for easy input of bending specifications and adjustments.

Material Handling Capabilities

Look for machines that can accommodate various rod sizes and materials to ensure versatility in production.

Maintenance and Support

Consider the availability of maintenance services and support from the manufacturer. A reliable machine with excellent after-sales support can save you time and money in the long run.

Software Integration

Modern machines often come with software that integrates with existing systems, enabling seamless operation and data management.

6. Best Practices for Optimizing Productivity

To maximize the benefits of automatic U bolt bending machines, implement the following best practices.

Regular Maintenance

Routine maintenance is vital to keep machines running efficiently. Schedule regular inspections and servicing to prevent breakdowns.

Employee Training

Invest in training programs for your operators to ensure they can effectively use and troubleshoot the machines.

Process Optimization

Continuously analyze the production process to identify bottlenecks and areas for improvement. Utilize data from machine operations to inform decisions.

7. Common Challenges and Solutions

While automatic U bolt bending machines offer significant advantages, they also come with challenges.

Initial Investment Costs

The cost of acquiring automatic machines can be high. However, consider it a long-term investment that pays off through increased efficiency and reduced labor costs.

Learning Curve

Operators may face a learning curve when transitioning from manual to automatic processes. Comprehensive training can help mitigate this challenge.

Maintenance Requirements

While automation reduces labor needs, machines still require regular maintenance. Establish a maintenance schedule to keep machines operating smoothly.

8. Future Trends in U Bolt Bending Technology

As technology evolves, so do U bolt bending machines. Here are some anticipated trends.

Smart Technology Integration

The integration of IoT (Internet of Things) technology allows machines to communicate with each other, enabling real-time monitoring and data collection.

Advanced Materials

The use of advanced materials and alloys will lead to more durable U bolts, necessitating the development of machines capable of handling these materials.

Green Manufacturing Practices

With rising environmental concerns, manufacturers are increasingly focusing on eco-friendly practices. Future machines may prioritize energy efficiency and sustainable materials.

9. Frequently Asked Questions

What is an automatic U bolt bending machine?

An automatic U bolt bending machine is a specialized piece of equipment that automates the bending process of metal rods into the shape of U bolts.

How does automation improve productivity?

Automation improves productivity by increasing speed, reducing errors, and minimizing labor costs, allowing manufacturers to produce more in less time.

Are automatic U bolt bending machines suitable for small businesses?

Yes, these machines can be beneficial for small businesses looking to improve efficiency and product quality. Various models cater to different production scales.

What materials can be used with U bolt bending machines?

These machines can typically handle a range of materials, including steel, aluminum, and other metals, depending on the specific machine's capabilities.

How do I maintain my automatic U bolt bending machine?

Regular maintenance includes routine inspections, cleaning, lubrication, and software updates. It’s essential to follow the manufacturer’s guidelines for optimal performance.

10. Conclusion

Investing in automatic U bolt bending machines can dramatically enhance productivity in manufacturing operations. By understanding the workings of these machines, recognizing the importance of productivity, and implementing best practices, manufacturers can significantly improve efficiency and output. As technology continues to evolve, embracing these advancements will position businesses for long-term success in a competitive landscape. With the right machinery, organizations can meet customer demands swiftly while maintaining high-quality standards.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us