The Top 5 Advantages of Investing in an Automatic U Bolt Bending Machine

Summary:

The Top 5 Advantages of Investing in an Automatic U Bolt Bending Machine

Introduction to Automatic U Bolt Bending Machines

In the ever-evolving landscape of manufacturing, efficiency and precision are paramount. Traditional methods of producing U bolts, often characterized by manual labor and intricate processes, can be both time-consuming and prone to errors. Enter the **automatic U bolt bend

The Top 5 Advantages of Investing in an Automatic U Bolt Bending Machine

Introduction to Automatic U Bolt Bending Machines

In the ever-evolving landscape of manufacturing, efficiency and precision are paramount. Traditional methods of producing U bolts, often characterized by manual labor and intricate processes, can be both time-consuming and prone to errors. Enter the **automatic U bolt bending machine**, a game-changer that streamlines production while enhancing quality. This article delves into the top five advantages of investing in this cutting-edge technology, offering insight into how it can transform your manufacturing operations.

1. Improved Efficiency and Productivity

One of the standout benefits of an automatic U bolt bending machine is its ability to significantly boost **efficiency and productivity**. Unlike manual methods, which require multiple steps and considerable human intervention, automatic machines can perform the bending process swiftly and consistently.

The Speed Factor

Automatic machines operate at a much faster pace than human labor. With programmable settings, they can execute multiple bends in rapid succession. This speed not only reduces production time but also allows for higher output, enabling companies to meet growing demand without compromising quality.

Reduced Labor Costs

Investing in an automatic U bolt bending machine also translates into lower labor costs. With fewer workers needed to oversee the bending process, businesses can allocate resources more efficiently. This reduction in labor not only cuts costs but also minimizes the risks associated with human error, leading to a more streamlined production line.

2. Enhanced Precision and Quality Control

Precision is critical in manufacturing, especially in industries where U bolts play a vital role. Automatic U bolt bending machines are engineered to deliver unmatched accuracy, ensuring that every bend meets stringent specifications.

Consistency in Production

These machines are designed to maintain consistency throughout the production process. By using advanced technology and computer-controlled operations, an automatic U bolt bending machine can replicate the same results with every cycle, significantly reducing the chances of defects.

Quality Assurance Features

Many automatic U bolt bending machines come equipped with quality assurance features, such as sensors and monitoring systems. These systems continuously check for precision, allowing manufacturers to identify and rectify any issues before they escalate, thus maintaining high-quality standards.

3. Versatility in Production

Another compelling advantage of an automatic U bolt bending machine is its versatility. Manufacturers often require a range of U bolt sizes and specifications, and automatic machines can accommodate various designs without the need for extensive reconfiguration.

Adaptability to Different Specifications

Modern machines are equipped with programmable controls that allow operators to easily switch between different U bolt designs. This adaptability means businesses can quickly respond to changing customer demands or market trends without significant downtime.

Multi-Functional Capabilities

In addition to bending U bolts, many automatic machines can perform multiple functions such as cutting and threading. This multi-functionality eliminates the need for additional equipment, saving space and resources in the manufacturing facility.

4. Increased Safety Measures

Safety is always a priority in manufacturing environments, and automatic U bolt bending machines enhance workplace safety in several ways.

Minimized Human Intervention

By automating the bending process, the need for manual labor is significantly reduced. This decrease in human intervention lowers the risk of workplace accidents and injuries, creating a safer environment for employees.

Built-in Safety Features

Most automatic U bolt bending machines come with built-in safety features, such as emergency stops and protective enclosures. These features not only ensure the safety of the operators but also protect the machinery from potential damage during operation.

5. Long-Term Cost Savings

While the initial investment in an automatic U bolt bending machine may seem substantial, the long-term cost savings can be significant.

Lower Operational Costs

As mentioned, the reduction in labor costs and the increased efficiency of automatic machines contribute to lower operational costs. Over time, these savings can accumulate, providing a strong return on investment.

Reduction in Material Waste

Automatic U bolt bending machines are designed for precision, which means less material is wasted during the bending process. This reduction in waste not only benefits the environment but also translates to further savings for the business.

Conclusion

Investing in an automatic U bolt bending machine is a strategic decision that can yield numerous advantages for manufacturers. From improved efficiency and enhanced precision to increased safety and long-term cost savings, these machines represent a significant leap forward in manufacturing technology. As businesses strive to stay competitive in a dynamic market, leveraging the benefits of an automatic U bolt bending machine can be a crucial factor in achieving operational excellence. Embrace the future of manufacturing and consider how this investment can transform your production processes for the better.

FAQs

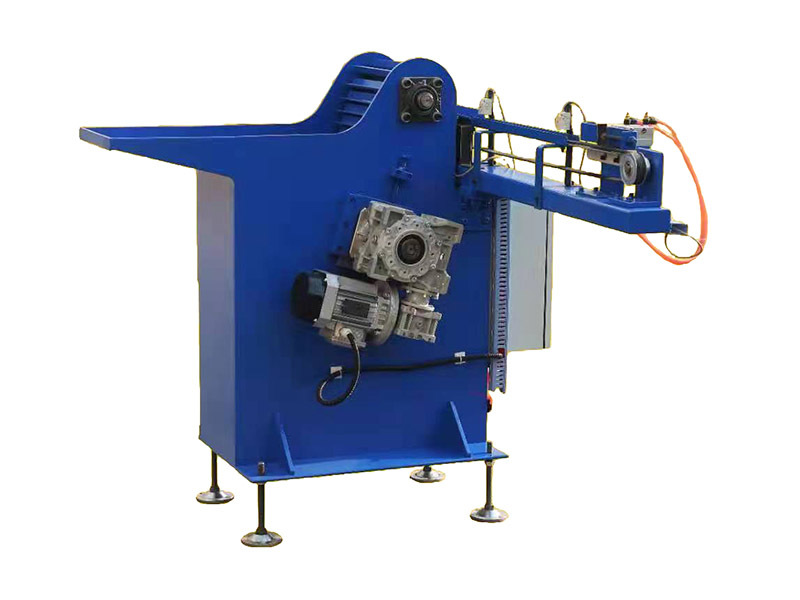

1. What is an automatic U bolt bending machine?

An automatic U bolt bending machine is a specialized piece of equipment designed to bend metal rods into U-shaped bolts with high precision and efficiency, using automated processes.

2. How does an automatic U bolt bending machine improve productivity?

These machines enhance productivity by performing bending tasks much faster than manual methods, allowing for higher output and reduced production times.

3. Are automatic U bolt bending machines easy to operate?

Yes, most automatic U bolt bending machines are designed with user-friendly interfaces, allowing operators to program and control the machine with relative ease.

4. What types of materials can be used with an automatic U bolt bending machine?

Automatic U bolt bending machines can typically work with various metal materials, including mild steel, stainless steel, and other alloys.

5. How can I ensure the quality of U bolts produced using an automatic bending machine?

Investing in machines with built-in quality assurance features, such as sensors and monitoring systems, can help maintain high-quality standards throughout the production process.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us