Understanding the Functionality of U Bolt Bending Machines in Manufacturing

Summary:

In the realm of manufacturing and processing machinery, the U Bolt Bending Machine stands out for its specialized functionality in shaping metal rods into U-shaped bolts, which are crucial for numerous applications across various industries. This machine is specifically designed to efficiently bend metal materials with precision, ensuring the production of U bolts that meet stringent quality stand

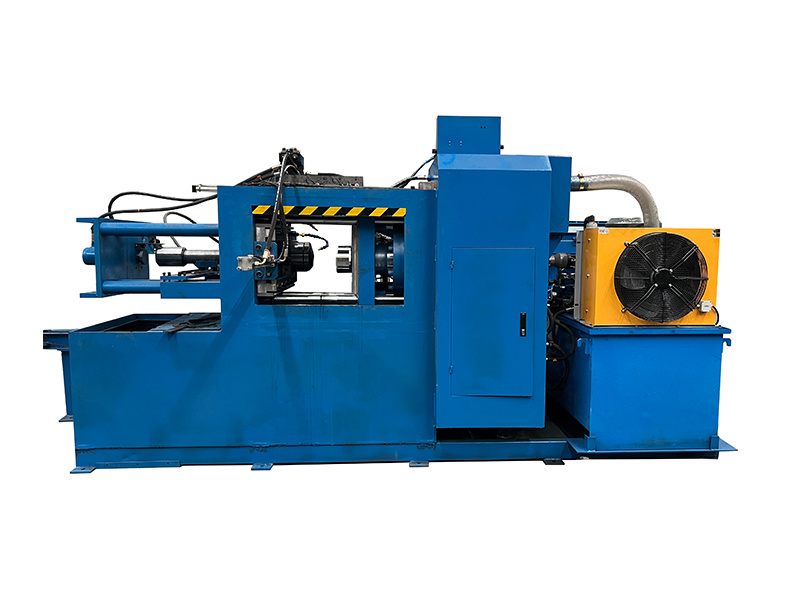

In the realm of manufacturing and processing machinery, the U Bolt Bending Machine stands out for its specialized functionality in shaping metal rods into U-shaped bolts, which are crucial for numerous applications across various industries. This machine is specifically designed to efficiently bend metal materials with precision, ensuring the production of U bolts that meet stringent quality standards.

The operation of a U Bolt Bending Machine typically involves several key components, including a bending device, a fixture to hold the workpiece in place, and control mechanisms that allow operators to set the desired bending angle and dimensions. The machine's bending device utilizes hydraulic or mechanical force to apply pressure to the metal rod, smoothly transforming it into the desired U-shape. This process can be tailored to accommodate different materials, such as steel or aluminum, which are commonly used for U bolts.

One of the significant advantages of using a U Bolt Bending Machine is its ability to produce high volumes of U bolts with consistency and accuracy. This efficiency not only speeds up the production process but also minimizes waste, as the machine optimizes material usage. Additionally, modern U Bolt Bending Machines often come equipped with digital controls and software that enhance user experience, allowing for quick adjustments and precise programming. These features contribute to improved productivity and reduced operational costs.

U Bolt Bending Machines find applications in various sectors, including automotive, construction, and machinery manufacturing. In the automotive industry, for example, properly shaped U bolts are essential for securing components and ensuring structural integrity. In construction, U bolts are crucial for anchoring structures and providing stability. The versatility of these machines makes them indispensable tools for manufacturers looking to produce reliable and durable U bolts that meet the demands of their respective industries.

Moreover, maintenance and regular calibration of U Bolt Bending Machines are vital for ensuring optimal performance over time. Operators should follow manufacturer guidelines for upkeep, including regular inspections and parts replacements, to prolong the lifespan of the machinery and maintain consistent output quality.

In summary, U Bolt Bending Machines play a pivotal role in the manufacturing process by providing precision, efficiency, and durability in U bolt production. Understanding their functionality and applications helps businesses make informed decisions when integrating this machinery into their production lines, ultimately enhancing overall operational effectiveness.

The operation of a U Bolt Bending Machine typically involves several key components, including a bending device, a fixture to hold the workpiece in place, and control mechanisms that allow operators to set the desired bending angle and dimensions. The machine's bending device utilizes hydraulic or mechanical force to apply pressure to the metal rod, smoothly transforming it into the desired U-shape. This process can be tailored to accommodate different materials, such as steel or aluminum, which are commonly used for U bolts.

One of the significant advantages of using a U Bolt Bending Machine is its ability to produce high volumes of U bolts with consistency and accuracy. This efficiency not only speeds up the production process but also minimizes waste, as the machine optimizes material usage. Additionally, modern U Bolt Bending Machines often come equipped with digital controls and software that enhance user experience, allowing for quick adjustments and precise programming. These features contribute to improved productivity and reduced operational costs.

U Bolt Bending Machines find applications in various sectors, including automotive, construction, and machinery manufacturing. In the automotive industry, for example, properly shaped U bolts are essential for securing components and ensuring structural integrity. In construction, U bolts are crucial for anchoring structures and providing stability. The versatility of these machines makes them indispensable tools for manufacturers looking to produce reliable and durable U bolts that meet the demands of their respective industries.

Moreover, maintenance and regular calibration of U Bolt Bending Machines are vital for ensuring optimal performance over time. Operators should follow manufacturer guidelines for upkeep, including regular inspections and parts replacements, to prolong the lifespan of the machinery and maintain consistent output quality.

In summary, U Bolt Bending Machines play a pivotal role in the manufacturing process by providing precision, efficiency, and durability in U bolt production. Understanding their functionality and applications helps businesses make informed decisions when integrating this machinery into their production lines, ultimately enhancing overall operational effectiveness.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us