Understanding the Benefits and Functionality of Automatic U Bolt Bending Machines

Summary:

In the manufacturing and processing machinery industry, Automatic U Bolt Bending Machines play a pivotal role in the efficient production of U-shaped bolts. These machines are designed to automate the bending process, ensuring precision, consistency, and enhanced productivity. The automatic feature not only reduces manual labor but also minimizes the chances of errors, which is crucial for maintai

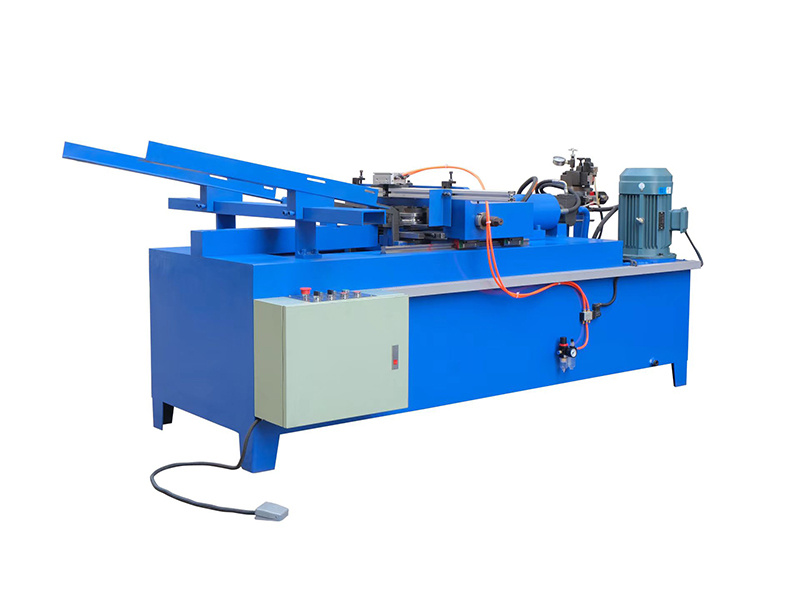

In the manufacturing and processing machinery industry, Automatic U Bolt Bending Machines play a pivotal role in the efficient production of U-shaped bolts. These machines are designed to automate the bending process, ensuring precision, consistency, and enhanced productivity. The automatic feature not only reduces manual labor but also minimizes the chances of errors, which is crucial for maintaining high-quality standards in production.

One of the primary benefits of utilizing an Automatic U Bolt Bending Machine is the speed at which it can operate. Traditional bending methods often require considerable time and labor, but with automation, the bending process can be completed in a fraction of the time. This efficiency leads to increased output, allowing manufacturers to meet higher demands without compromising quality.

Moreover, these machines are engineered for versatility. They can accommodate various sizes and specifications of U bolts, making them suitable for different applications across industries. Whether in automotive manufacturing, construction, or machinery assembly, the adaptability of Automatic U Bolt Bending Machines ensures that businesses can cater to a diverse range of client needs.

Precision is another hallmark of these machines. With advanced control systems and digital interfaces, operators can easily input specific measurements and parameters, resulting in accurately bent U bolts that adhere to strict tolerances. This level of precision is particularly important in industries where safety and reliability are paramount.

Additionally, the integration of Automatic U Bolt Bending Machines into production lines can contribute significantly to cost savings. By reducing labor costs and material waste, businesses can enhance their overall profitability. Furthermore, the durability of these machines often results in lower maintenance costs, providing a long-term return on investment.

In conclusion, Automatic U Bolt Bending Machines represent a significant advancement in the manufacturing process, combining speed, accuracy, and versatility. As industries continue to evolve, the demand for efficient and reliable machinery will only increase. By understanding the functionalities and advantages of these machines, professionals can make informed decisions that enhance production efficiency and product quality. Investing in Automatic U Bolt Bending Machines not only streamlines operations but also positions manufacturers for success in an increasingly competitive market.

One of the primary benefits of utilizing an Automatic U Bolt Bending Machine is the speed at which it can operate. Traditional bending methods often require considerable time and labor, but with automation, the bending process can be completed in a fraction of the time. This efficiency leads to increased output, allowing manufacturers to meet higher demands without compromising quality.

Moreover, these machines are engineered for versatility. They can accommodate various sizes and specifications of U bolts, making them suitable for different applications across industries. Whether in automotive manufacturing, construction, or machinery assembly, the adaptability of Automatic U Bolt Bending Machines ensures that businesses can cater to a diverse range of client needs.

Precision is another hallmark of these machines. With advanced control systems and digital interfaces, operators can easily input specific measurements and parameters, resulting in accurately bent U bolts that adhere to strict tolerances. This level of precision is particularly important in industries where safety and reliability are paramount.

Additionally, the integration of Automatic U Bolt Bending Machines into production lines can contribute significantly to cost savings. By reducing labor costs and material waste, businesses can enhance their overall profitability. Furthermore, the durability of these machines often results in lower maintenance costs, providing a long-term return on investment.

In conclusion, Automatic U Bolt Bending Machines represent a significant advancement in the manufacturing process, combining speed, accuracy, and versatility. As industries continue to evolve, the demand for efficient and reliable machinery will only increase. By understanding the functionalities and advantages of these machines, professionals can make informed decisions that enhance production efficiency and product quality. Investing in Automatic U Bolt Bending Machines not only streamlines operations but also positions manufacturers for success in an increasingly competitive market.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us