An In-Depth Exploration of Inverted Wire Drawing Machine Technology: Advancements and Applications

Summary:

An In-Depth Exploration of Inverted Wire Drawing Machine Technology: Advancements and Applications

Table of Contents

1. Introduction to Inverted Wire Drawing Machines

2. The Mechanics of Inverted Wire Drawing

3. Key Benefits of Inverted Wire Drawing Machines

4. Applications of Inverted Wire Drawing Technology

4.1 Automotive Industry

4.2 Electrical Manufacturing

4.3 Construction and Infrastructure

An In-Depth Exploration of Inverted Wire Drawing Machine Technology: Advancements and Applications

Table of Contents

1. Introduction to Inverted Wire Drawing Machines

2. The Mechanics of Inverted Wire Drawing

3. Key Benefits of Inverted Wire Drawing Machines

4. Applications of Inverted Wire Drawing Technology

4.1 Automotive Industry

4.2 Electrical Manufacturing

4.3 Construction and Infrastructure

5. Comparison with Traditional Wire Drawing Machines

6. Future Trends in Wire Drawing Technology

7. Maintenance and Best Practices for Inverted Wire Drawing Machines

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Introduction to Inverted Wire Drawing Machines

In the realm of metal processing, **inverted wire drawing machines** stand out as pivotal innovations that significantly enhance the productivity and efficiency of wire production. Unlike traditional wire drawing techniques, inverted wire drawing technology implements a unique mechanism that utilizes gravity to its advantage, making the drawing process more streamlined. These machines have revolutionized the production of wire in various sectors, offering improved control and precision.

2. The Mechanics of Inverted Wire Drawing

Understanding the mechanics of inverted wire drawing machines is essential for manufacturers looking to optimize their production processes. This technology employs a distinctive design where the drawing capstan is positioned below the die block. As the wire is pulled through the die, it descends under its weight, thereby reducing the force required to draw the wire. This configuration not only increases operational efficiency but also minimizes wear on the machine components.

Key components of an inverted wire drawing machine include:

- **Die Block**: The part through which the wire is drawn.

- **Capstan**: The rotating wheel that pulls the wire through the die.

- **Payoff Stand**: The mechanism that feeds the wire into the drawing process.

- **Take-up Reel**: Where the finished wire is wound.

The interaction of these components allows for a smoother operation, reducing the risk of defects in the final product.

3. Key Benefits of Inverted Wire Drawing Machines

Investing in inverted wire drawing technology offers several key benefits:

- **Enhanced Efficiency**: The inverted design allows for faster wire drawing speeds, significantly boosting production rates.

- **Lower Energy Consumption**: With reduced force requirements, these machines consume less energy, leading to cost savings in operations.

- **Improved Quality Control**: The gravity-assisted drawing process minimizes issues such as wire necking and breakage, resulting in higher-quality wire outputs.

- **Versatility**: Inverted wire drawing machines can handle various materials, including stainless steel and copper, making them suitable for diverse applications.

By leveraging these advantages, manufacturers can stay competitive in the market by increasing output while maintaining premium quality.

4. Applications of Inverted Wire Drawing Technology

Inverted wire drawing technology finds extensive use across various industries. Its applications span a wide range, demonstrating its versatility and significance.

4.1 Automotive Industry

In the automotive sector, inverted wire drawing machines play a crucial role in producing high-strength wires for various components, including springs, cables, and connectors. The ability to produce durable wire with precise specifications is essential in meeting the rigorous demands of modern automotive design.

4.2 Electrical Manufacturing

The electrical manufacturing industry relies heavily on wire drawing technology to create copper and aluminum wires that are used in electrical wiring, connectors, and circuit boards. The enhanced conductivity and reliability of wires produced through inverted wire drawing directly impact the efficiency of electrical components.

4.3 Construction and Infrastructure

In the construction and infrastructure sectors, inverted wire drawing machines are utilized to produce reinforcing bars and other structural components. The strength and durability of the wire are critical for ensuring the safety and longevity of construction projects.

5. Comparison with Traditional Wire Drawing Machines

When comparing inverted wire drawing machines to traditional models, several distinctions emerge. Traditional wire drawing machines typically employ a horizontal design where the die block is positioned above the capstan. While this method has been effective, it often requires more force to draw the wire, resulting in higher energy consumption and increased wear on machinery.

In contrast, the inverted design offers a more efficient method of wire drawing. By minimizing the energy required for the process, inverted machines not only operate more economically but also produce wires with fewer defects. Consequently, manufacturers can enjoy longer machine lifespans and reduced maintenance costs.

6. Future Trends in Wire Drawing Technology

As industries continue to evolve, so too does the technology behind wire drawing machines. Future trends in this field include:

- **Automation and Smart Technology**: The integration of automation and AI in wire drawing processes will lead to more precise control and monitoring, further enhancing efficiency.

- **Sustainability Practices**: Emphasizing energy-efficient designs and processes that minimize environmental impact will become increasingly important as eco-friendly practices gain traction in manufacturing.

- **Advanced Materials**: Innovations in materials science will result in the development of wires with superior properties, further expanding the applications of inverted wire drawing machines.

By staying abreast of these trends, manufacturers can adapt to changing market demands and leverage new technologies to improve their production processes.

7. Maintenance and Best Practices for Inverted Wire Drawing Machines

Proper maintenance of inverted wire drawing machines is essential for ensuring optimal performance and longevity. Key practices include:

- **Regular Inspections**: Schedule routine inspections to identify and address wear and tear on critical components such as the die block and capstan.

- **Lubrication**: Maintain proper lubrication levels to reduce friction and wear on moving parts.

- **Calibration**: Regularly calibrate the machine settings to ensure consistent product quality and adherence to specifications.

- **Training**: Ensure that all operators are well-trained in the operation and maintenance of the machines to minimize the risk of operator error.

Implementing these practices not only enhances machine performance but also contributes to overall production efficiency.

8. Frequently Asked Questions (FAQs)

What is an inverted wire drawing machine?

An inverted wire drawing machine is a specialized piece of equipment designed to draw wire through a die using a gravity-assisted mechanism, enhancing efficiency and reducing energy consumption.

What are the main advantages of using inverted wire drawing machines?

The primary advantages include increased efficiency, lower energy consumption, improved wire quality, and versatility in handling different materials.

In which industries are inverted wire drawing machines commonly used?

These machines are widely used in the automotive, electrical manufacturing, and construction industries, among others.

How do inverted wire drawing machines compare to traditional machines?

Inverted machines generally offer better energy efficiency and produce higher-quality wire with fewer defects compared to traditional wire drawing machines.

What maintenance practices should be followed for inverted wire drawing machines?

Regular inspections, lubrication, calibration, and operator training are essential maintenance practices to enhance performance and longevity.

9. Conclusion

Inverted wire drawing machine technology represents a significant advancement in the field of metal processing. By harnessing the power of gravity, these machines deliver enhanced efficiency, lower energy costs, and superior quality wire outputs. As industries continue to evolve, the importance of adopting innovative technologies like inverted wire drawing machines cannot be overstated. Manufacturers who invest in this technology will not only improve their production processes but also position themselves for success in an increasingly competitive market. Understanding the mechanics, benefits, and applications of inverted wire drawing machines will empower businesses to make informed decisions that drive growth and innovation in their operations.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

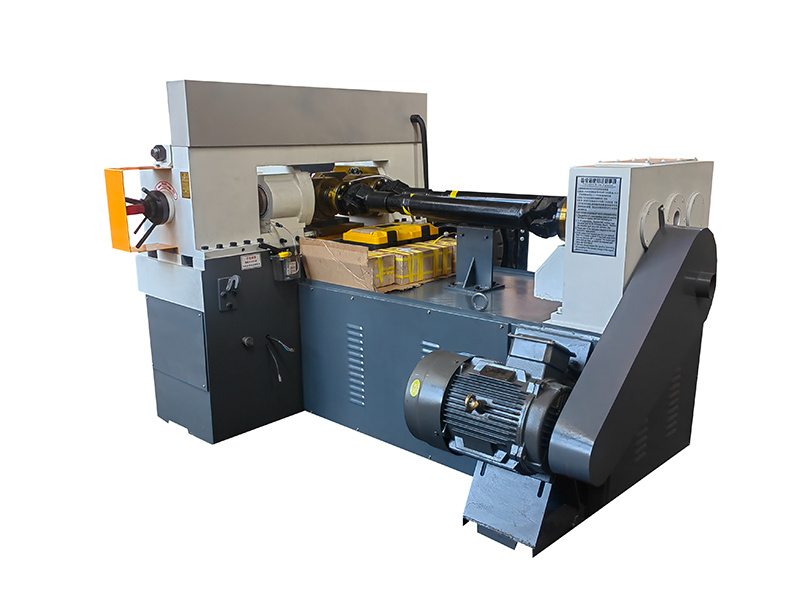

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us