Understanding the Double Head Chamfering Machine: A Key Tool in Metalworking

Summary:

---

The Double Head Chamfering Machine is an innovative solution for efficiently creating chamfers on metal components. Chamfers are beveled edges that facilitate ease of assembly, improve aesthetics, and help prevent injuries from sharp edges. This machine, with its dual-head design, enhances productivity by allowing simultaneous processing of two edges, significantly reducing cycle times and imp

---

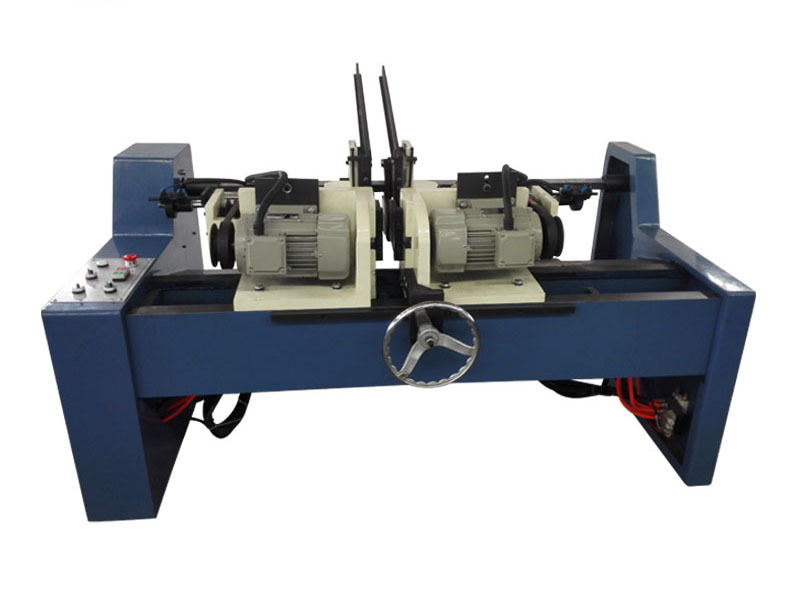

The Double Head Chamfering Machine is an innovative solution for efficiently creating chamfers on metal components. Chamfers are beveled edges that facilitate ease of assembly, improve aesthetics, and help prevent injuries from sharp edges. This machine, with its dual-head design, enhances productivity by allowing simultaneous processing of two edges, significantly reducing cycle times and improving efficiency.

One of the standout features of the Double Head Chamfering Machine is its adjustable cutting angles. Operators can easily set the machine to create various bevels, making it suitable for a wide range of applications in different manufacturing sectors. From automotive to aerospace and general metal fabrication, this machine proves invaluable in creating precise and consistent chamfers on diverse materials.

In addition to its versatility, the Double Head Chamfering Machine is designed for user-friendly operation. Many models come equipped with digital displays and control systems that enable operators to monitor and adjust settings with precision. This feature not only enhances the accuracy of the chamfering process but also minimizes the risk of human error, ensuring that each piece meets the required specifications.

Moreover, the machine's robust construction and high-quality components contribute to its durability and reliability. Businesses investing in a Double Head Chamfering Machine can expect long-term performance with minimal maintenance, leading to a reduction in operational costs over time. The reliability of the machine ensures that production schedules are maintained, enabling manufacturers to meet deadlines and customer expectations.

Safety is another crucial aspect of the Double Head Chamfering Machine. With features such as automatic shut-off mechanisms and protective enclosures, operators can work confidently, knowing that safety protocols are in place. This focus on safety not only protects personnel but also reduces the likelihood of equipment damage, further enhancing operational efficiency.

Applications of Double Head Chamfering Machines extend beyond simple edge preparation. They are also utilized in processes where precise edge finishing is required, such as in welding preparation and final surface treatment. The ability to achieve high-quality finishes consistently makes this machine a staple in modern manufacturing environments.

In summary, the Double Head Chamfering Machine offers remarkable advantages for manufacturers seeking to improve their chamfering processes. With its dual-head configuration, adjustable angles, user-friendly controls, and emphasis on safety, it stands out as a pivotal tool in the arsenal of machining equipment. Understanding its features and benefits can empower businesses to make informed decisions about their manufacturing capabilities and enhance their overall productivity.

The Double Head Chamfering Machine is an innovative solution for efficiently creating chamfers on metal components. Chamfers are beveled edges that facilitate ease of assembly, improve aesthetics, and help prevent injuries from sharp edges. This machine, with its dual-head design, enhances productivity by allowing simultaneous processing of two edges, significantly reducing cycle times and improving efficiency.

One of the standout features of the Double Head Chamfering Machine is its adjustable cutting angles. Operators can easily set the machine to create various bevels, making it suitable for a wide range of applications in different manufacturing sectors. From automotive to aerospace and general metal fabrication, this machine proves invaluable in creating precise and consistent chamfers on diverse materials.

In addition to its versatility, the Double Head Chamfering Machine is designed for user-friendly operation. Many models come equipped with digital displays and control systems that enable operators to monitor and adjust settings with precision. This feature not only enhances the accuracy of the chamfering process but also minimizes the risk of human error, ensuring that each piece meets the required specifications.

Moreover, the machine's robust construction and high-quality components contribute to its durability and reliability. Businesses investing in a Double Head Chamfering Machine can expect long-term performance with minimal maintenance, leading to a reduction in operational costs over time. The reliability of the machine ensures that production schedules are maintained, enabling manufacturers to meet deadlines and customer expectations.

Safety is another crucial aspect of the Double Head Chamfering Machine. With features such as automatic shut-off mechanisms and protective enclosures, operators can work confidently, knowing that safety protocols are in place. This focus on safety not only protects personnel but also reduces the likelihood of equipment damage, further enhancing operational efficiency.

Applications of Double Head Chamfering Machines extend beyond simple edge preparation. They are also utilized in processes where precise edge finishing is required, such as in welding preparation and final surface treatment. The ability to achieve high-quality finishes consistently makes this machine a staple in modern manufacturing environments.

In summary, the Double Head Chamfering Machine offers remarkable advantages for manufacturers seeking to improve their chamfering processes. With its dual-head configuration, adjustable angles, user-friendly controls, and emphasis on safety, it stands out as a pivotal tool in the arsenal of machining equipment. Understanding its features and benefits can empower businesses to make informed decisions about their manufacturing capabilities and enhance their overall productivity.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us