Maximizing Efficiency with Automatic Single-Head Chamfering Machines in Manufacturing

Summary:

In modern manufacturing, the need for precision and efficiency is paramount. One of the innovative solutions that have emerged to meet these demands is the automatic single-head chamfering machine. This specialized equipment is designed to create beveled edges on metallic parts, ensuring smooth transitions and reducing the risk of sharp edges that can cause safety issues. The integration of such m

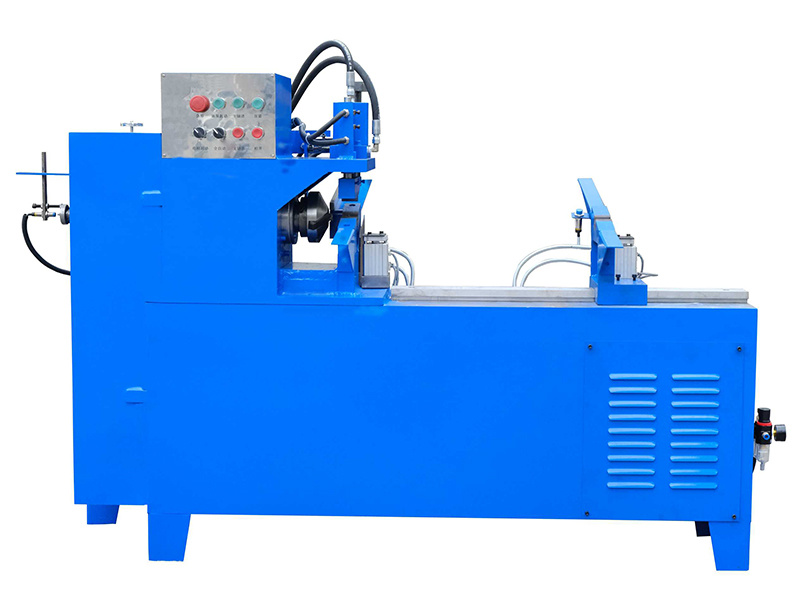

In modern manufacturing, the need for precision and efficiency is paramount. One of the innovative solutions that have emerged to meet these demands is the automatic single-head chamfering machine. This specialized equipment is designed to create beveled edges on metallic parts, ensuring smooth transitions and reducing the risk of sharp edges that can cause safety issues. The integration of such machines into your production line can significantly boost both productivity and product quality.

Automatic single-head chamfering machines operate with remarkable accuracy, utilizing advanced technology to deliver consistent results. The key feature of these machines is their ability to automate the chamfering process, which traditionally required extensive manual labor and expertise. With automation, manufacturers can minimize human error and reduce production times, allowing for a more streamlined operation. This not only enhances efficiency but also allows skilled workers to focus on more complex tasks that require human intervention.

One of the primary benefits of using automatic single-head chamfering machines is their versatility. These machines can handle a variety of materials, including steel, aluminum, and other alloys, making them suitable for diverse applications across different industries. Additionally, they can be configured to accommodate various chamfer angles, which can be crucial for meeting specific design requirements of different projects.

Furthermore, automatic single-head chamfering machines contribute to improved safety standards in the workplace. By ensuring that edges are properly beveled, these machines help eliminate sharp edges that can lead to injuries during handling or assembly. This focus on safety is increasingly important as companies prioritize worker well-being and strive to comply with industry regulations.

Another critical aspect to consider is the cost-effectiveness of implementing these machines into your manufacturing processes. Although the initial investment in automatic single-head chamfering machines might be significant, the long-term savings in labor costs, material waste reduction, and increased production speed can justify the expenditure. Companies can achieve a quicker return on investment by scaling up production and enhancing product quality, ultimately leading to greater customer satisfaction and loyalty.

In summary, automatic single-head chamfering machines represent a significant advancement in machining technology, offering numerous benefits for manufacturers. By automating the chamfering process, businesses can achieve higher precision, improved safety, and greater efficiency in their operations. Investing in such technology may prove to be a strategic decision that enhances competitiveness in an increasingly demanding market. For manufacturers seeking to optimize their production processes, the adoption of automatic single-head chamfering machines is a step towards achieving operational excellence.

Automatic single-head chamfering machines operate with remarkable accuracy, utilizing advanced technology to deliver consistent results. The key feature of these machines is their ability to automate the chamfering process, which traditionally required extensive manual labor and expertise. With automation, manufacturers can minimize human error and reduce production times, allowing for a more streamlined operation. This not only enhances efficiency but also allows skilled workers to focus on more complex tasks that require human intervention.

One of the primary benefits of using automatic single-head chamfering machines is their versatility. These machines can handle a variety of materials, including steel, aluminum, and other alloys, making them suitable for diverse applications across different industries. Additionally, they can be configured to accommodate various chamfer angles, which can be crucial for meeting specific design requirements of different projects.

Furthermore, automatic single-head chamfering machines contribute to improved safety standards in the workplace. By ensuring that edges are properly beveled, these machines help eliminate sharp edges that can lead to injuries during handling or assembly. This focus on safety is increasingly important as companies prioritize worker well-being and strive to comply with industry regulations.

Another critical aspect to consider is the cost-effectiveness of implementing these machines into your manufacturing processes. Although the initial investment in automatic single-head chamfering machines might be significant, the long-term savings in labor costs, material waste reduction, and increased production speed can justify the expenditure. Companies can achieve a quicker return on investment by scaling up production and enhancing product quality, ultimately leading to greater customer satisfaction and loyalty.

In summary, automatic single-head chamfering machines represent a significant advancement in machining technology, offering numerous benefits for manufacturers. By automating the chamfering process, businesses can achieve higher precision, improved safety, and greater efficiency in their operations. Investing in such technology may prove to be a strategic decision that enhances competitiveness in an increasingly demanding market. For manufacturers seeking to optimize their production processes, the adoption of automatic single-head chamfering machines is a step towards achieving operational excellence.

PREVIOUS:

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us