Maximizing Efficiency with the Automatic U Bolt Bending Machine

Summary:

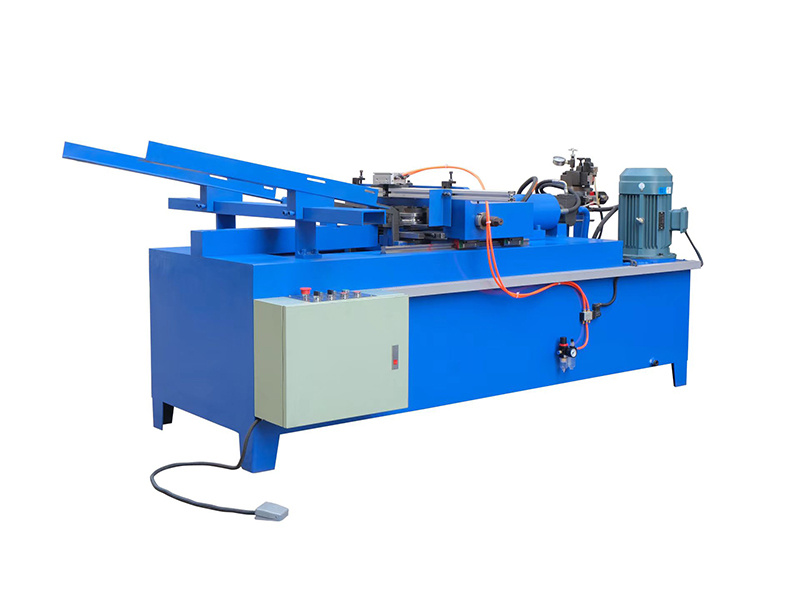

The Automatic U Bolt Bending Machine is a pivotal tool in the manufacturing and processing machinery industry, particularly for applications requiring precision and efficiency in bending U-shaped bolts. This advanced machine streamlines the production process by automating the bending operation, thereby significantly reducing labor costs and increasing output.

One of the primary benefits of the Au

The Automatic U Bolt Bending Machine is a pivotal tool in the manufacturing and processing machinery industry, particularly for applications requiring precision and efficiency in bending U-shaped bolts. This advanced machine streamlines the production process by automating the bending operation, thereby significantly reducing labor costs and increasing output.

One of the primary benefits of the Automatic U Bolt Bending Machine is its ability to produce consistent and high-quality bends. Traditional manual bending methods often result in variations due to human error, which can lead to product inconsistencies and increased waste. With an automatic machine, you can achieve precise angles and dimensions every time, ensuring that each component meets strict quality standards. This precision is particularly crucial in industries such as automotive, construction, and manufacturing, where the integrity of components is paramount.

Another advantage of using an Automatic U Bolt Bending Machine is the reduction in production time. These machines are designed for high-speed operation, allowing for rapid processing of materials. Many models come equipped with user-friendly interfaces and programmable settings, enabling operators to quickly switch between different bending tasks without extensive downtime. This flexibility not only enhances productivity but also allows manufacturers to respond swiftly to changing market demands.

In addition to speed and accuracy, the Automatic U Bolt Bending Machine is built for durability and reliability. These machines often incorporate robust materials and advanced engineering techniques, ensuring they can withstand the rigors of continuous operation. Investing in a high-quality bending machine reduces maintenance costs and downtime, contributing to a more efficient production line.

Furthermore, the incorporation of safety features in modern Automatic U Bolt Bending Machines cannot be overlooked. Many models include automatic shut-off systems, safety guards, and emergency stop buttons, prioritizing operator safety in the workplace. By minimizing the risk of accidents, these machines help create a safer working environment, which is essential for maintaining employee morale and productivity.

In summary, the Automatic U Bolt Bending Machine is an invaluable asset for any manufacturer looking to enhance productivity, ensure quality, and maintain safety. By automating the bending process, manufacturers can achieve greater efficiency and flexibility, ultimately leading to improved profitability. As industries continue to evolve, investing in advanced machinery like the Automatic U Bolt Bending Machine will be crucial for staying competitive in the marketplace.

One of the primary benefits of the Automatic U Bolt Bending Machine is its ability to produce consistent and high-quality bends. Traditional manual bending methods often result in variations due to human error, which can lead to product inconsistencies and increased waste. With an automatic machine, you can achieve precise angles and dimensions every time, ensuring that each component meets strict quality standards. This precision is particularly crucial in industries such as automotive, construction, and manufacturing, where the integrity of components is paramount.

Another advantage of using an Automatic U Bolt Bending Machine is the reduction in production time. These machines are designed for high-speed operation, allowing for rapid processing of materials. Many models come equipped with user-friendly interfaces and programmable settings, enabling operators to quickly switch between different bending tasks without extensive downtime. This flexibility not only enhances productivity but also allows manufacturers to respond swiftly to changing market demands.

In addition to speed and accuracy, the Automatic U Bolt Bending Machine is built for durability and reliability. These machines often incorporate robust materials and advanced engineering techniques, ensuring they can withstand the rigors of continuous operation. Investing in a high-quality bending machine reduces maintenance costs and downtime, contributing to a more efficient production line.

Furthermore, the incorporation of safety features in modern Automatic U Bolt Bending Machines cannot be overlooked. Many models include automatic shut-off systems, safety guards, and emergency stop buttons, prioritizing operator safety in the workplace. By minimizing the risk of accidents, these machines help create a safer working environment, which is essential for maintaining employee morale and productivity.

In summary, the Automatic U Bolt Bending Machine is an invaluable asset for any manufacturer looking to enhance productivity, ensure quality, and maintain safety. By automating the bending process, manufacturers can achieve greater efficiency and flexibility, ultimately leading to improved profitability. As industries continue to evolve, investing in advanced machinery like the Automatic U Bolt Bending Machine will be crucial for staying competitive in the marketplace.

Latest News

AISEN Four axis nut tapping machine ready for shipment to Russia

Four axis nut tapping machine for DIN934 M8,M10 Standard hex nut is ready for shipping to Russia by land transportation.

AISEN machinery inverted wire drawing machine

We hope to cooperate with more customers for mutual development and benefits. You are welcome to contact us